Introduction

- Conical slag valve is widely used in the discharge of boiler slag.

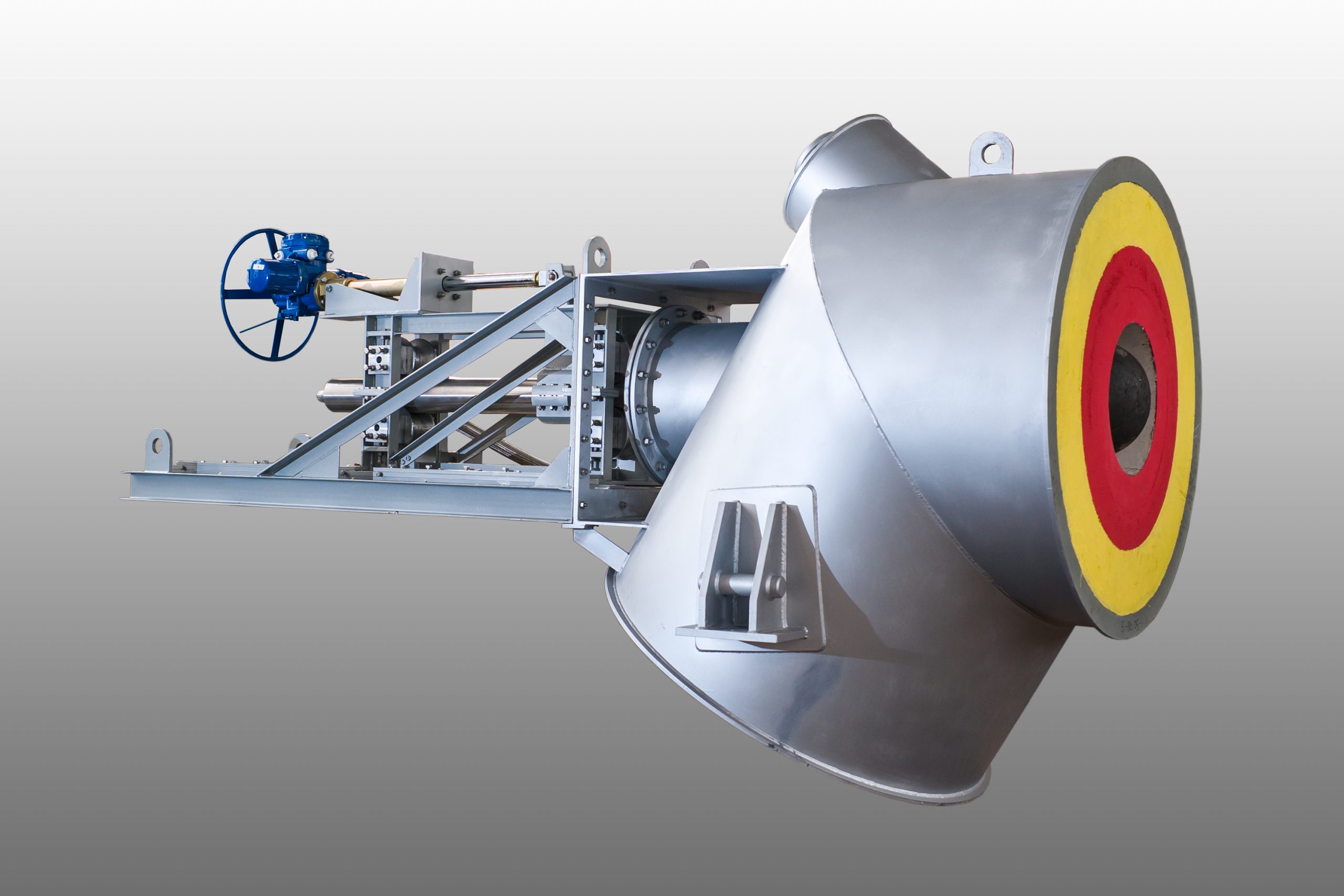

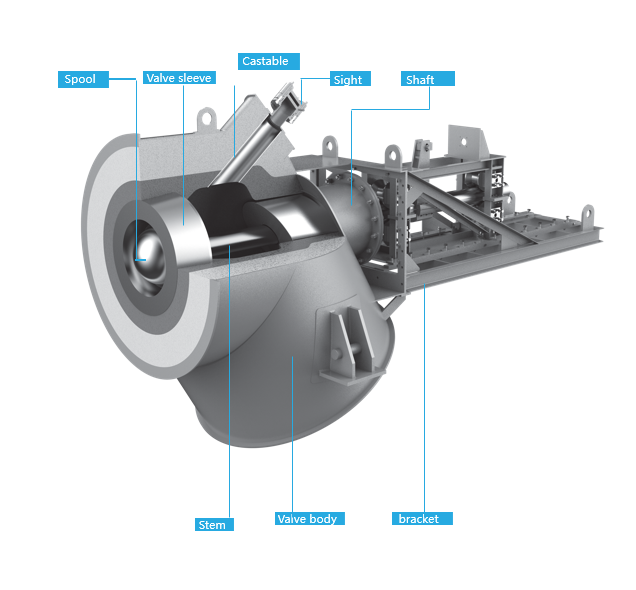

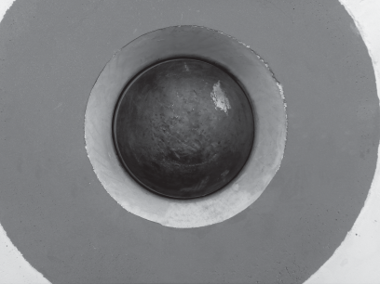

When the boiler slag is discharged, the electric actuator adjusts the valve stem to make the valve core leave the valve sleeve and the slag inlet is opened. The slag enters the cone-shaped slag discharge valve through the slag inlet and is discharged from the slag outlet. When discharging is stopped, the electric actuator drives the valve stem to move so that the valve core and the valve sleeve are tightly closed and the slag inlet is closed. The position and distance of the spool movement are controlled by the travel switch, and the slag discharge amount is adjusted by controlling the opening of the spool and the valve sleeve.

Feature

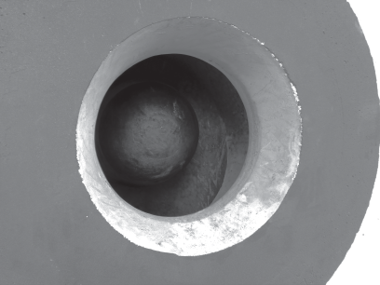

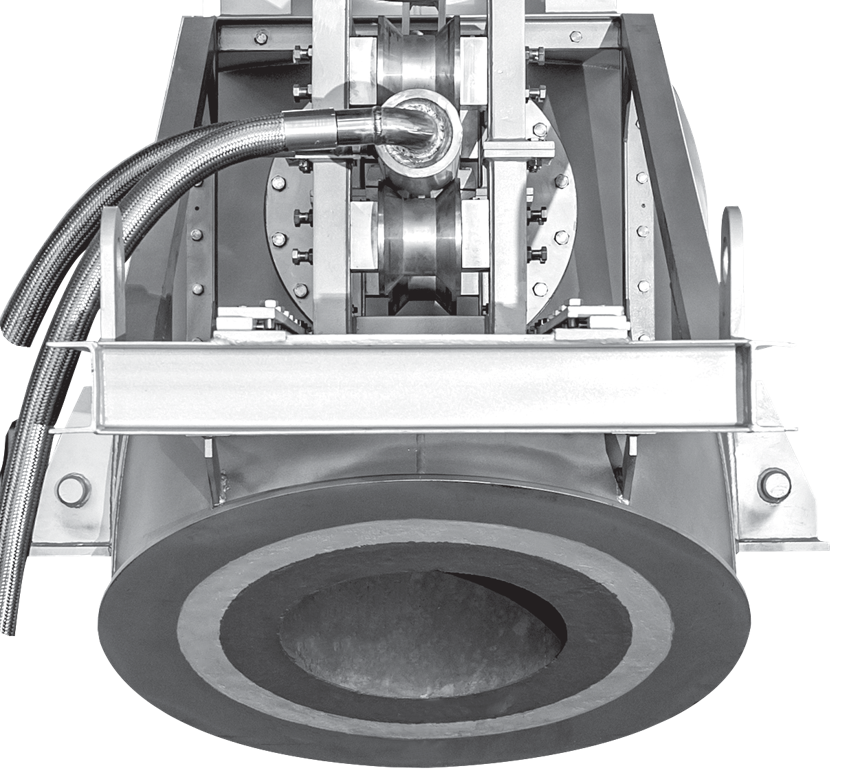

- The valve body has a three-layer structure, using structural steel as a support, lined with wear-resistant casting materials, which not only ensures the wear resistance of the valve body and slag contact parts, but also makes the body surface temperature less than 50°C. In order to prevent the casting material from falling off, special handle nails are needed in the wear-resistant casting material to make the structure stronger.

- The core components are made of high-temperature and wear-resistant materials, and the operating temperature is as high as 2190°F. When the valve cooling water is cooled internally, the temperature of the valve stem is reduced, which can prevent the deformation of the valve stem from affecting the seal and ensure that there is no deformation and blockage during use.

- The sight glass device adopts a double-layer structure, has high strength and high transparency, can withstand pressure, can better observe the slag slagging situation, and also ensure personal safety.

- The upper and lower bearing limit mechanism is adopted to make the friction resistance smaller, the operation more stable and more flexible.

- The valve body sleeve adopts a special streamlined structure, which not only ensures smooth slag discharge of the valve body, but also can adjust the slag discharge flow of the boiler by adjusting the size of the valve core and valve sleeve, which can meet the needs of different operating conditions of the CFB boiler.

- The cone-shaped slag valve has an integral structure, and the wear-resistant casting and heat curing of the equipment have been completed before leaving the factory.

- Compact structure, stable and reliable, can use on-site manual operation, automatic operation mode, and can also achieve remote control (DCS control).

Working Principle

Slagging

When the slag is discharged, the electric actuator adjusts the valve core to make the valve core leave the valve sleeve, and the slag enters from the inlet, and the slag is poured into the conical slag discharge valve, and the slag is discharged.

Stop slagging

When the slag discharge is stopped, the electric actuator drives the valve stem to move, so that the valve core and the valve sleeve are tightly connected, close to the slag port.

Adjust the flow

The position and distance of the spool movement are controlled by an electric actuator. The size of the slag discharge port is adjusted by controlling the size of the spool and valve sleeve, so as to realize the adjustment of the slag discharge flow.

Specification

Applicable medium: slag/bottom slag

Medium size: ≤ 100mm

Medium temperature: ≤ 1000℃

Moving torque: 15-40KN

Sealing air pressure: 70-180KPa

Cooling water temperature: 30℃

Cooling water outlet temperature: 85℃

Water quality requirements: softened water

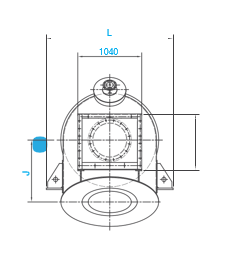

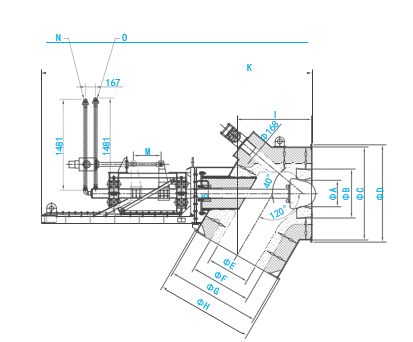

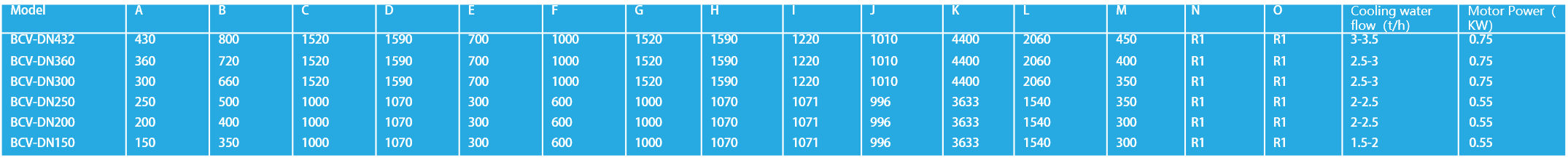

Dimension